Case study: Detuning and Re-design of Steam Turbine Blades

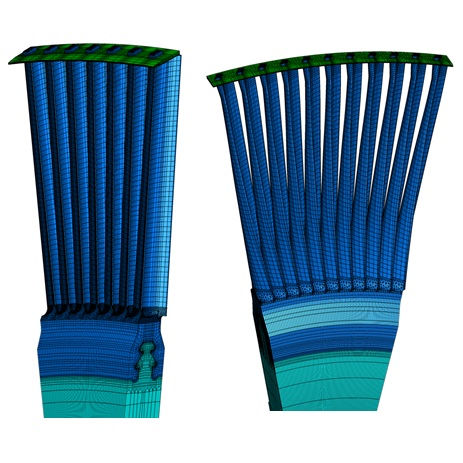

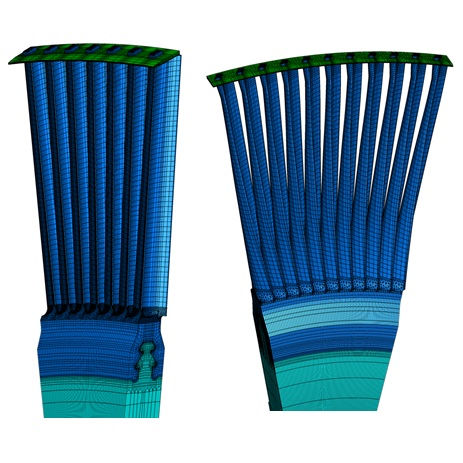

Stage: Stage 15 and 16 in a steam turbine with an earlier design

Issue: Crack and rupture found at the first hook of straddle mounted root

Objectives: Root cause analysis and blade re-design

Diagnosis: High cycle fatigue (HCF) due to resonance of synchronous vibration was identified as the driver

Solutions: Modification of airfoil profile guided by analysis to de-tune the frequency

Background

-

Cracks and rupture were found at the first hook of straddle mounted root after a relative short period of time in service.

-

TTI was solicited to perform modal analyses and identify potential resonant modes of vibration.

-

The main objective of the study was to evaluate various de-tuning strategies and optimize configurations to mitigate the resonance issue for both stages.

Summary of Analyses

-

At-speed frequencies and mode shapes of the bladed-disk structure were calculated by FEA analysis. Interference diagrams were established to identify potential resonant modes.

-

Several options of de-tuning strategies including re-profiling airfoil, re-grouping and use of different shroud material were examined.

-

Parametric studies were performed to achieve an acceptable solution in regards to margins to the resonant frequencies and level of steady stresses.

-

Increase of fillet radii was also studied to prolong fatigue life.